Research Article

Francisco Rios

Francisco Rios

Centro Interdisciplinario de Investigaciones en Tecnologías y Desarrollo social para el NOA- (CIITED), CONICET-Facultad de Ingeniería. Universidad Nacional de Jujuy. Ítalo Palanca 10. 4600, San Salvador de Jujuy, Jujuy. Argentina.

E-mail: frios8078@gmail.com

Cristina Rocha

Cristina Rocha

CEB - Centre of Biological Engineering, University of Minho, 4710-057 Braga, Portugal.

E-mail: cmrochainv@gmail.com

Duarte Torres

Duarte Torres

Faculty of Nutrition and Food Sciences, University of Porto, Rua Dr. Roberto Frias, 4200-465 Porto, Portugal.

E-mail: dupamato@fcna.up.pt

Maria do Pilar Gonçalves

Maria do Pilar Gonçalves

REQUIMTE, LAQV, Departamento de Engenharia Química, Faculdade de Engenharia, Universidade do Porto, Rua Dr. Roberto Frias, 4200-465 Porto, Portugal.

E-mail: pilarg@fe.up.pt

Manuel Lobo

Manuel Lobo

Centro

Interdisciplinario de Investigaciones en Tecnologías y Desarrollo social para

el NOA- (CIITED), CONICET-Facultad de Ingeniería. Universidad Nacional de

Jujuy. Ítalo Palanca 10. 4600, San Salvador de Jujuy, Jujuy. Argentina.

Norma Samman

Norma Samman

Corresponding

Author

Centro Interdisciplinario de Investigaciones en Tecnologías y Desarrollo social para el NOA- (CIITED), CONICET-Facultad de Ingeniería. Universidad Nacional de Jujuy. Ítalo Palanca 10. 4600, San Salvador de Jujuy, Jujuy. Argentina.

E-mail: normasamman@gmail.com; nsamman@fi.unju.edu.ar; Tel: +54 3888 650675

Abstract

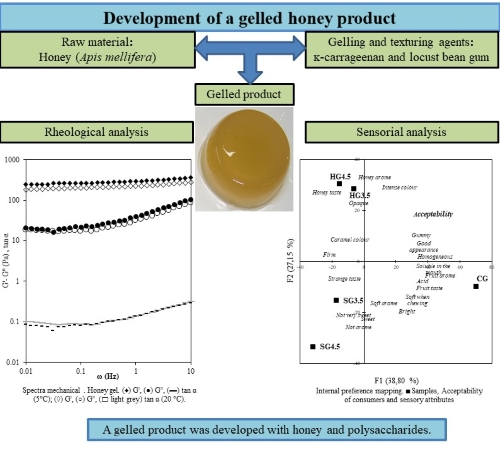

The work aimed to develop a gelled

product based on honey and a polysaccharide system. Polysaccharides used as gelling and

texturizing agents were ĸ-carrageenan (Car) and locust bean gum (LBG). The gel

with honey was developed using a rotational central composite design (RCCD) with

three variables (concentration of polysaccharides, Car percentage in polysaccharides, and honey content) and Bloom Strength (BS)

was used as a response variable. The BS of the gelled

system increased linearly with the content in Car and LBG used as gelling and

texturizing agents. The Car-LBG system showed maximum values at 64.85% of Car

and 35.15 % of LBG. Honey concentration in the Car-LBG system increased BS to a

maximum value of 14.47g/100g. The rheological profile (Gꞌ, Gꞌꞌ, tan δ) of

the obtained product showed the typical behavior of polysaccharide gels. The

gelation (Tg = 44.5±0.4 °C) and melting (Tm = 66.1±0.2

°C) temperatures were determined. The attributes that could increase the gelled

product's acceptance were identified: aroma and taste of honey. The product had

significant amounts of honey (sweetener) and adequate sensory properties that

make it attractive for the formulation of commercial gels using

polysaccharides. This novel product has the potential to expand the use

of honey and polysaccharides in the food industry.

Abstract Keywords

Gels,

honey, carrageenan, locust bean gum, bloom strength, acceptability.

1. Introduction

Honey is a natural product, known and used since ancient times for its sensory, biological, and therapeutic properties [1]. Argentina is a producer and exporter of honey this country has honey-producing regions with different characteristics, including the Yungas region (Cloud ecoregion, Andean forest and mountain jungle) in the northwest, whose honey was studied and characterized. Monofloral honey corresponding to native species stood out due to their higher frequency of occurrence: Salix humboldtiana, Baccharis sp. and Ziziphus mistol [2, 3].

Honey is a supersaturated solution of different carbohydrates with the predominance of fructose, glucose, and to a lesser proportion, sucrose, oligosaccharides, and micronutrients [2, 4]. Honey has functional properties such as antioxidant, anti-inflammatory, antibacterial, anti-fungicidal, hepatoprotective, and anti-atherosclerotic effects. These properties are mainly attributed to phenolic compounds, including different groups of flavonoids and their derivatives [1, 5].

Beehive products have been used in different cereals, candy, and sweet products for their sensory properties [6, 7]. Gelled foods represent an alternative product that could be used to introduce nutritional and functional compounds beneficial to health into the diet [8]. According to its chemical composition, physical, and rheological characteristics and sensorial properties, honey could be used in the formulation of gel-like desserts. However, due to the low degree of polymerization (<4) of honey carbohydrates, forming a gelled structure is impossible without the addition of other compounds [8]. Commonly, the main ingredient in gelled food is edible gelatin, which is partially hydrolyzed collagen with low nutritional value and refined sugars, mainly sucrose [9]. Polysaccharides are widely used in the food and pharmaceutical industry to provide a specific structure and texture [10-12]. The κ-carrageenan (Car) is the least sulphated fraction of carrageenan, a natural polysaccharide extracted from certain red seaweeds, that can form thermo-reversible gels, influenced by the presence and concentration of certain ions. It is well known that the properties of Car gels can be improved by the addition of locust bean gum (LBG) [13, 14]. The use of honey could cause changes in the structure of the gels, so the texture and sensory properties of the Car-LBG system could be modified, determining its use as a functional sweetener [15].

In gelled foods, different instrumental methods (rheology, texture) can be used to adequately describe their properties. However, in the development of food products, along with instrumental analysis, sensory analysis is necessary to study consumer perception [16]. The sensory analysis provides a complete description of the characteristics of a product that determine consumer preference. It is a useful tool to develop new food products, to describe and study the effect of any ingredient, and also to guide the reformulation of products.

To investigate

the possibility of adding honey as the main ingredient in a gelled product, this

work aimed to develop a product similar to gelatine

dessert using honey as its main sweetener and the Car- LBG mixed gel system.

2. Materials and methods

2.1 Raw

materials

The honey (Apis mellifera) used

for this work was unifloral with the predominant pollen Baccharis sp. (56%) from the Yungas area, Jujuy, Argentina [2]. Honey was harvested directly from beekeepers.

A composite sample (10 kg) was prepared by carefully mixing the primary samples

following the general guidelines on sampling [17]. The

composite sample was transferred immediately to the laboratory, and stored in a

fresh (23 ± 2 °C) and dark place until use.

The polysaccharides used as gelling and texturing agents were Car (E407; GELLOGEN™ BW 56) and LBG (E410; VISCOGUMTM BCR 13/250), both from CARGILLTM (Spain). Commercial gelatin was used as a reference of texture and sensorial characteristics, to compare it with the product to be developed. Commercial bovine gelatine powders were obtained from a local supermarket (Jujuy, Argentina).

2.2 Gelled

product formulation design

2.2.1 Experimental

design

To determine the formulation of the gels, the independent variables selected were the total concentration of polysaccharides in the gel (X1: g total polysaccharides/100 g gel); X2: Car percentage (g Car *100/ g polysaccharides); and honey solids in the gel (X3: g honey solids/100 g gel). The effect of the independent variables and their interaction with the characteristics of the gel was measured by determining the Bloom Strength (BS), used as the response in the experimental design. The assays were conducted using a rotational central composite design (RCCD) with three factors (n=3), two levels (2) including six axial points and 3 repetitions at the central point, as described in Table 1. The values of the variables X1, X2 and X3 were determined so that the BS of the gelled product matched that of a commercial gelatine dessert (BS=0.33±0.01 N).

Table 1. Value of variables and response (BS) of RCCD

|

Assay |

X1 |

X2 |

X3 |

BS (N) |

|

S1 |

0.8 (-1) |

36.2 (-1) |

11.1 (-1) |

0.032±0.001 |

|

S2 |

1.7 (1) |

36.2 (-1) |

11.1 (-1) |

0.370±0.019 |

|

S3 |

0.8 (-1) |

83.8 (1) |

11.1 (-1) |

0.118±0.006 |

|

S4 |

1.7 (1) |

83.8 (1) |

11.1 (-1) |

0.466±0.013 |

|

S5 |

0.8 (-1) |

36.2 (-1) |

28.9 (1) |

0.082±0.005 |

|

S6 |

1.7 (1) |

36.2 (-1) |

28.9 (1) |

0.386±0.020 |

|

S7 |

0.8 (-1) |

83.8 (1) |

28.9 (1) |

0.112±0.009 |

|

S8 |

1.7 (1) |

83.8 (1) |

28.9 (1) |

0.350±0.014 |

|

S9 |

0.5

(-1.68) |

60.0 (0) |

20.0 (0) |

0.044±0.002 |

|

S10 |

2.0

(1.68) |

60.0 (0) |

20.0 (0) |

0.717±0.023 |

|

S11 |

1.25 (0) |

20.0

(-1.68) |

20.0 (0) |

0.057±0.005 |

|

S12 |

1.25 (0) |

100.0

(1.68) |

20.0 (0) |

0.177±0.007 |

|

S13 |

1.25 (0) |

60.0 (0) |

5.0

(-1.68) |

0.407±0.036 |

|

S14 |

1.25 (0) |

60.0 (0) |

35.0

(1.68) |

0.324±0.011 |

|

S16 |

1.25 (0) |

60.0 (0) |

20.0 (0) |

0.408±0.011 |

|

S17 |

1.25 (0) |

60.0 (0) |

20.0 (0) |

0.384±0.017 |

X1: Total polysaccharides content (g/100 g gel)

X2: Car percentage (g Car *100/ g polysaccharides)

X3: Soluble solid

content of honey (g/100 g gel)

( ) Codified variables

BS: Bloom

strength in Newton (N).

A quadratic

polynomial model (Equation 1) was applied to fit with the experimental data

(Table 1) using regression model to evaluate and correlate Y, the predicted response

in function of the independent variables XK:

where k is the number of variables, β0 is a constant term, ε is the residual associated with the experiment and βi, βii, βij, are coefficients of the terms of linear interactions and quadratic polynomial model. The validity of the model was evaluated using the F statistic, lack of fit test and R2 coefficient of determination.

2.2.2 Gels preparation

Gels were prepared following the directives of [18, 19] with modifications, according to the rheological properties of the polysaccharides used [13]. Car and LBG were dispersed in distilled water under constant stirring for one hour at room temperature. Then the mixture was stirred for 30 min at 85 °C to dissolve the polysaccharides. Honey was added to the mixture in the final polysaccharides dissolution stage and stirred for 5 min. Finally, the solutions were cooled to room temperature and then to 7±2 °C, and left to stabilize the gel for 16- 18 h before measuring their textural properties.

2.2.3

Gel texture analysis

The BS of the gels was used as the response variable in the experimental design. The BS was determined by a penetration test at a speed of 1 mm s-1, using a texture analyzer (TA-XT2, Stable Micro Systems Ltd., Godalming, UK) with a 0.5” diameter cylindrical plunger with a sharp edge.

In order to compare the acceptability of formulated products and commercial, further rheological and sensorial analyses were performed. The gelled product determined by eq. 1, was formulated with different sweeteners (Sucrose and Honey) at different pH (3.5 and 4.5). i) HG4.5: honey gel elaborated at pH 4.5 (corresponding to the pH of honey); ii) HG3.5: honey gel elaborated at pH 3.5 using citric/citrate buffer (corresponding to pH of the commercial product), iii) SG4.5: sucrose gel instead solids of honey at pH 4.5, and iv) SG3.5: sucrose gel at pH 3.5.

2.3 Gel

rheology analysis

The rheological properties were measured in a stress-controlled rheometer AR-G2 (TA Instruments, Delaware, USA) using a parallel plate (40 mm diameter, gap 800 μm). Each sample was placed directly on the rheometer plate (pre-heated to 70ºC) and covered with liquid paraffin to prevent dehydration. After a 5 minutes conditioning step, the gelling process was monitored by cooling the solution from 70 to 5 °C at a rate of 1 °C/min and a constant frequency of 1 Hz. After allowing the sample to equilibrate at 5 °C and 1 Hz for 30 min (time sweep), a frequency sweep (mechanical spectrum) was performed in the range of 0.01 and 10 Hz. Subsequently, the temperature was increased to 20 °C, at a constant rate of 1 °C/min and constant frequency of 1 Hz, then it was stabilized again for 30 min at the same temperature. A frequency sweep (0.01 and 10 Hz) was performed at 20 °C for 30 min. Finally, the sample melting process was followed during a heating ramp carried out from 20 to 70 °C, at a constant rate of 1 °C/min and a constant frequency of 1 Hz.

A strain sweep from 0.05 to 25% at 20 °C was previously conducted to determine the linear viscoelastic region of the gels. Based on this test, a 2% strain was chosen to perform the small amplitude test, as it ensured that "irreversible damages" did not occur in the samples. The rheological determinations were performed in triplicate and the results were reported as the average measurements.

2.4 Sensorial evaluation

A panel consisted of 10 evaluators with experience in sensory description of foods and 25 frequent consumers of gelatine desserts were employed to generate sensory descriptors of different commercial gelatine products (five) and the sample optimized was obtained in 2.2.

First, the Acceptability for each sample was evaluated using a 9-point hedonic scale. Second, evaluators and frequent consumers were asked to answer the open-ended question to generate descriptors about gelatine desserts. Finally, twenty-five attributes were determined to describe the “gelled dessert” grouped in appearance (good appearance, bad appearance, caramel color, intense color, bright and opaque), taste (astringent, very sweet, sweet, not very sweet, intense, fruit, strange, acid and honey), aroma (fruit, honey, soft, not aroma) and texture (firm, gummy, homogeneous, soluble in the mouth, soft when chewing, rigid when chewing). The most accepted commercial gelatin sample was used as a reference for the comparison with the gelled product with honey.

The five samples, HG4.5, HG3.5, SG4.5, SG3.5, and the commercial product (CG) were subjected to Acceptability and Check-All-That-Apply (CATA) tests with 105 consumers to describe each sample and its IDEAL product [20]. Participants were between 18 and 50 years old and 60% were female. They were recruited in the area of the Facultad de Ingeniería – Universidad Nacional de Jujuy, Argentina. Participants were informed about the objective and characteristics of the sensorial evaluation. Along with the test form, participants voluntarily signed the informed consent form.

Then, the five samples were presented in plastic cups, numbered by a random three digits code. The test was completed after instructions were given by an interviewer and samples were presented following a randomized complete block design. Drinking water was provided next to the samples. A portion of approximately 20 g of product was given to each consumer. An acceptability test was performed, with a structured 9-point hedonic scale where numbers corresponded to "1 = I dislike a lot and 9 = I like a lot". For each sample, a CATA list of 25 attributes was presented to consumers to tick off the one that most accurately describes the product. Finally, a CATA list was presented to consumers so that they could indicate with which attributes each would define their IDEAL product [20]. Since the preset order of the CATA attributes affects the response of consumers, attributes were randomly distributed by software and organized in three lists randomly distributed among consumers [21].

2.5

Statistical analyses

The quantitative parameters were shown as mean value ± standard deviation. For analysis of variance quantitative data was used. Tukey’s test was used a posteriori at a significance level of p<0.05 to determine differences between samples.

To relate consumer preference and attributes of the different formulations on the internal preference map, the principal component analysis (PCA) was applied to Acceptability data. Formulation attributes determined by CATA were used as supplementary data. Correspondence analysis (CA) was applied to sensory data of appearance, taste, aroma and texture of the commercial, formulated and “IDEAL” desserts, to determine the most important attributes in their characterization.

Cochran's Q test was applied to frequency data in each attribute of CATA tests to statistically determine differences between the formulations [20]. Then, for the attributes that presented significant differences (p<0.05), the Marascuillo test was employed to compare multiple proportions for each attribute of samples for a confidence level of 95%. The XLSTAT software (Copyright© 2018 Addinsoft, Paris, France) was used for data analysis.

3. Results and discussion

3.1 Gelled product

3.1.1 Experimental design

Table

1 shows variation levels and interaction for the 3 independent variables (X1, X2 and X3) and the BS measured

experimentally. The analysis of variance indicated the statistically

significant terms (p<0.05) of the regression model of BS (Eq. 2). In

addition, the test of lack-of-fit of the model was not significant (p>0.05),

which indicates that the model was adequate for the observed data (Table 2). From

coefficients of Eq. 2, the variable X1

had the strongest positive effect on the BS

which increased linearly with the polysaccharides content. This was probably a

result of the increase in intermolecular unions among the polysaccharides to

form the gel network [13].

Table 2. ANOVA of the regression equation of the BS data

|

SD |

DF |

SS |

MS |

F |

Prob>F |

|

X1 |

1 |

0.4079 |

0.4079 |

2720.0 |

0.0004 |

|

X2 |

1 |

0.0104 |

0.0104 |

69.4 |

0.0141 |

|

X3 |

1 |

0.0028 |

0.0028 |

18.7 |

0.0495 |

|

X22 |

1 |

0.1325 |

0.1324 |

883.2 |

0.0011 |

|

X2X3 |

1 |

0.0045 |

0.0045 |

29.8 |

0.0319 |

|

X32 |

1 |

0.0029 |

0.0029 |

19.7 |

0.0473 |

|

Model |

8 |

0.0204 |

0.0025 |

17.0 |

0.0567 |

|

Lack of

fit |

2 |

0.0003 |

0.0001 |

||

|

Total |

16 |

0.5796 |

|||

|

R2

= 96.43 % |

|

SD: source of deviation; DF: degree of freedom, SS:

sum of squares, MS: Mean Square

X1: Total polysaccharides content (g/100 g gel)

X2: Car percentage (g Car *100/ g polysaccharides)

X3: Soluble solid

content of honey (g/100 g gel)

On

the other hand, X2 increased BS to a maximum due to a synergistic

effect between Car and LBG, and then BS

decreased due to the term of X22.

The X2 value that produces the gel

with maximum BS can be obtained from the

regression model (Car=64.85% and LBG=35.15 %,). This synergistic effect between

both polysaccharides was consistent with the informed by other authors [11, 13, 14].

Honey content (X3) had a lower gel stabilizing effect in the Car-LBG system than X1 and X2. The initial increase in BS from the addition of honey could be attributed to the ability of its sugars (fructose, glucose and sucrose) to interact with the joint areas of the polymers through hydrogen bonds. The concentration of honey in the system that maximizes BS was X3= 14.47 g solids of honey/100 g gel. Generally, depending on the type of polysaccharide, low concentrations of sugars tend to increase the strength of the gel’s network [22].

To determine the concentration of the independent variable X1, the BS of the gelled product was taken as that of commercial gelatine and calculated as 1.06 g polysaccharides /100 g gel.

The

viscoelastic moduli (G' and G") and the α angle of the samples during the test

time are

shown in Figure 1. The

points where G'=G" can be considered as the apparent gelling (Tg) and melting (Tm) temperatures of the

systems, for the tested conditions. During the cooling, the honey system (Figure

1a and b) showed a significantly (p<0.05) higher Tg (44.5±0.4 °C) compared to gel with sucrose (Tg 36.3±0.5 °C). During the heating

process, the gel-liquid transition occurs at a temperature at which the systems

reach sufficient energy to break the forces that keep it stable. The

temperature Tm (66.1±0.2

°C) of the gels with honey was significantly (p<0.05) higher than Tm (58.7±0.4 °C) of gels with

sucrose. A more extended pseudo-plateau in the system with honey means that it

remains for more time as a gel (Fig. 1a and 1b). The differences could be related to the

effect of the honey sugars and their hydroxyl groups as well as the minerals content

that induce a great number and type of bonds in the Car-LBG system [13]. The pH had no significant effect on the

rheological characteristics of the gels.

Figure 1. Rheological

measurements. The viscoelastic moduli and loss angle during the time of testing for a)

honey gel and b) sucrose gel. (◊) Gꞌ (black), (○) Gꞌꞌ (dark grey), (□) α (light grey). Spectra

mechanical for c) honey gel and d) sucrose gel. (♦) Gꞌ, (●) Gꞌꞌ, (▬) tan α (5°C); (◊) Gꞌ, (○) Gꞌꞌ, (- light grey) tan α (20 °C). Due to the complexity of the graphs, only

system data at pH=4.5 is shown

The behavior of the viscoelastic moduli (G' and G") and tan α of the systems towards frequency is shown in Fig. 1c and 1d). Gꞌ was higher than Gꞌꞌ on the mechanical spectrum, along the whole range of the analyzed frequencies at 5°C and 20°C, which is characteristic of viscoelastic gels [13]. The Gꞌꞌ moduli of all the systems showed a small angular frequency dependency, which was characteristic of the non-covalent intermolecular bonds as hydrogen bonds and Van der Waals weak interactions. The viscoelastic moduli between 5 and 20 °C were similar throughout the test. Therefore, although honey altered the structure of the Car-LBG system, the representative behavior of polysaccharides gels did not change. Furthermore, Fig. 2c and 2d showed an increase of the tan α that corresponds with the concavity of Gꞌꞌ, which is typical of κ-carrageenan gels [23]. The tan α was close to zero, indicating a prevalence of the elastic over the viscous behavior. However, the tan α in the system with honey displayed a higher dependence on the angular frequency, denoting a higher viscous character, which would be related to lower molecular weight, and a higher number of hydrogen bonds that honey sugars can form [24]. Accordingly, the increase in Gꞌꞌ and tan α in the system with honey would be related to the stabilization of the intermolecular bonds of carrageenan by sugars and ions, at the honey concentration used.

Figure 2. Internal preference mapping. Representation in the first two factors (F) of principal component analysis. a) Loadings plot and b) scores plot. (●) samples.

3.3 Sensorial analysis

3.3.1 Acceptability test

Table 3 shows the average Acceptability of consumers corresponding to the four-gelled products and CG. ANOVA applied to the Acceptability data of the samples determined significant differences (p <0.05) due to the effect of the experimental design variables (pH and sweeteners). The results showed that honey significantly increased (p<0.05) the Acceptability of gelled product compared to sucrose. The CG and HG4.5 samples showed the greatest Acceptability. On the other hand, the effect of pH was not significant (p <0.05), Table 3.

Table 3. Effect of sample and consumer variables on Acceptability of gelled products

Samples (Average ± SD) | Acceptability (Consumers, n=105) | p-value |

CG | 6.05±2.00a | 0.0245 |

HG4.5 | 5.80±1.66ab | |

HG3.5 | 5.50±1.73bc | |

SG4.5 | 5.13±1.55c | |

SG3.5 | 5.47±1.77bc |

a-c Different letters in the same file indicates statistically significant differences (p<0.05).

SD: standard deviation

CG: commercial gelatin

HG4,5: honey gel at pH =4.5

HG3,5: honey gel at pH =3.5

SG4,5: sucrose gel at pH =4.5

SG3,5: sucrose gel at pH =3.5

Fig. 2 shows the F1-F2 factors of the internal preference mapping applied to Acceptability and attributes data to determine the most influential attributes in consumer preference. The Acceptability of consumers and CATA data with frequency > 15% were used as supplementary variables. The first two factors explained 65.95% of the total variability of data.

The consumers that contributed to the acceptance of CG were correlated to the positive F1 axis by attributes (r> 0.85): fruity taste and aroma, homogeneous texture and soluble in the mouth. On the other hand, the consumers, related to the positive F2 axis, preferred honey gels, increasing the Acceptability of the aroma and taste attributes that convey the presence of honey. The knowledge of honey's presence in the gel formulation could increase its Acceptability, since the consumption and purchase trends of honey are strongly related to the fact that it is a natural, healthy, and nutritional sweetener [25, 26].

3.3.2 CATA analysis and Ideal product

Table 4 shows the attributes frequency (%) used to describe the samples and the IDEAL product by consumers. Cochran’s Q test determined significant differences in 12 attributes (excluding the IDEAL product). Good appearance and sweetness were the attributes with the highest frequency in the IDEAL product (> 60%), in both no significant difference (p <0.05) was observed between samples. While in the attributes soluble in the mouth, fruit aroma, and bright, the CG sample and IDEAL product presented higher value than the samples with honey. However, an increase in the intensity of these attributes would approximate the honey gels to the IDEAL product.

Table 4. Frequency of use of the attributes by consumers to describe the samples

and their IDEAL product

Attributes | CG | HG4.5 | HG3.5 | SG4.5 | SG3.5 | IDEAL | p-value |

Good appearance | 40 | 30 | 38 | 30 | 34 | 67 | 0.2421 |

Sweet | 37 | 31 | 35 | 38 | 45 | 66 | 0.2735 |

Firm | 37a | 72b | 66b | 76b | 64b | 62 | 0.0001 |

Soluble in the mouth | 50a | 26b | 31ab | 26b | 33ab | 59 | 0.0001 |

Fruit aroma | 67a | 2b | 3b | 1b | 4b | 57 | 0.0001 |

Bright | 62a | 38b | 41ab | 47ab | 59ab | 57 | 0.0015 |

Soft when chewing | 42 | 37 | 39 | 40 | 38 | 48 | 0.9463 |

Fruit taste | 49a | 3b | 5b | 7b | 8b | 44 | 0.0001 |

Homogeneous | 37 | 32 | 30 | 33 | 31 | 41 | 0.4562 |

Intense colour | 24 | 30 | 28 | 19 | 22 | 32 | 0.1051 |

Honey aroma | 7a | 85b | 82b | 3a | 7a | 30 | 0.0001 |

Soft aroma | 25 | 22 | 19 | 23 | 30 | 30 | 0.2775 |

Caramel colour | 56 | 62 | 66 | 64 | 61 | 30 | 0.6084 |

Honey taste | 4a | 65b | 61b | 8a | 14ac | 28 | 0.0001 |

Not very sweet | 14a | 19ac | 17ac | 34bc | 28ac | 14 | 0.0005 |

Acid | 37a | 2b | 11b | 4b | 13b | 14 | 0.0001 |

Gummy | 19 | 18 | 17 | 16 | 17 | 13 | 0.9715 |

Not aroma | 16a | 12a | 11a | 74b | 63b | 3 | 0.0001 |

Opaque | 6a | 32b | 27b | 17ab | 6a | 3 | 0.0001 |

Strange taste | 6a | 16ab | 26b | 32b | 22b | 0 | 0.0001 |

Frequency of use (%) of the attributes.

p-value <0.05 of each attribute indicates significant differences between samples according to Cochran’s Q test

a-c Different letters in the same files indicate significant differences of attributes between gels (excluding IDEAL sample) according to the Marascuillo test for a confidence level of 95%.

Consumers did not perceive significant differences in texture attributes: homogeneous, soft when chewing and gummy between the samples and the commercial gel. Therefore, the polysaccharides and the concentrations employed would be suitable to replace the commercial gelling agent (gelatine E428). The acid attribute is one of the least frequent in the IDEAL sample, which confirmed the low influence of pH on sample preference.

Of all the attributes perceived by consumers, aroma and taste were the most used to describe the samples. The fruit arome and honey arome were the most frequently perceived in CG and honey gels, respectively. Therefore, attributes of honey gelled products would be strongly associated with the honey type used, since sensory properties vary depending on their botanical origin [27].

Fig. 3 shows the dimensions (D) I-II representation of the CA to associate CATA attributes with samples. Moreover, Acceptability and the IDEAL product were used as supplementary data. The first two dimensions of the CA explained 97.85% of the data´s total inertia. The CA had high explained variability, due to the similarity of the attributes of texture and appearance of the samples (near the barycenter), confirming that the polysaccharides used are suitable gelling agents.

Figure 3. Correspondence analysis map of D1-D2 dimensions for a) attributes and b) (●) samples. (◊) Acceptability and Ideal product

The consumers associated the taste and aroma attributes with the different samples, which allowed them to differentiate between those containing honey, sugar, or commercial samples. Similar to that reported by [20], IDEAL product was associated with the attributes that contribute most to the Acceptability of the consumers. The IDEAL product, located on the positive axis of DI-DII was strongly associated with the CG and honey gels and consequently with its characteristic attributes. Therefore, aroma and taste were the determining attributes and should be modified in a reformulation to increase consumer preference.

4. Conclusions

The texture and rheological analyses showed that the obtained product presented a global behavior typical of polysaccharide gels. The rheological parameters confirmed that honey alters the Car-LBG system. Honey modifies the structural system by modifying the interactions and forces that keep stabilized the Car-LBG system. However, a food product with honey and polysaccharides was developed, with adequate rheological, texture, and sensory properties. This product incorporates the honey sensory properties of aroma and taste that would increase consumer preference. Therefore, honey provides the properties of beehive products, expanding the potential applications of raw materials. For the less preferred formulations of this model, the sensory analysis allowed the identification of the attributes to be modified in those products to increase the Acceptability of the samples after a reformulation. This novel product has the potential to expand the use of honey and polysaccharides in the food industry.

Authors’ contributions

Conceptualization, F.R., N.S., C.R. and M.L.; Methodology, F.R., C.R., D.T.; Software, F.R.; Validation, F.R. and M.L.; Formal Analysis, F.R., C.R., D.T. and M.L.; Investigation, F.R., C.R, D.T. and N.S., Resources, F.R. and M.L., M.G.; Data Curation, F.R.; Writing – Original Draft Preparation, F.R., C.R. and N.S.; Visualization, F.R, M.L., C.R. and N.S. Supervision, F.R, C.R., M.G. and N.S.

Acknowledgements

This work was supported by the National Council of Scientific and Technical Research (CONICET)- and SECTER - National University of Jujuy, Argentina.

Funding

This research received no specific grant from any funding agency.

Availability of data and materials

All data will be made available on request according to the journal policy

Institutional review board statement/approval (Ethical consent)

Ethics approval was not required for this research.

References

1.

González-Montemayor,

Á.M.; Flores-Gallegos, A.C.; Serrato-Villegas, L.E.; López-Pérez,

M.G.; Montañez-Sáenz, J.C.; Rodríguez-Herrera, R. Honey and Syrups: Healthy and

Natural Sweeteners with Functional Properties. In Natural Beverages.

Academic Press, 2019, 143-177.

2.

Rios, F.; Sanchez,

A.C.; Lobo, M.; Lupo, L.; Coelho, I.; Castanheira, I.; Samman, N.A. A chemometric

approach: characterization of quality and authenticity of artisanal honeys from Argentina. J. Chemom. 2014, 28, 834-843. https://doi.org/10.1002/cem.2654.

3.

Rios, F.; Lobo, M.; Castanheira, I.;

Delgado, I.; Nascimiento, A.; Samman, N. Chemometric

and multielement techniques for the exploratory analysis of honey quality from

different geographical origin. J. Agric. Food Sci. Biotechnol. 2024, 2(1),

54-63. https://doi.org/10.58985/jafsb.2024.v02i01.36.

4.

Perna, A.; Grassi, G.; Gambacorta, E.; Simonetti, A.

Minerals content in Basilicata region (southern Italy) honeys from areas with

different anthropic impact. Int. J. Food Sci. Technol. 2021, 1-8.

https://doi.org/10.1111/ijfs.15112.

5.

Mokaya, H.O.; Bargul, J.L.; Irungu, J.W.;

Lattorff, H.M.G. Bioactive constituents, in vitro radical scavenging and

antibacterial activities of selected Apis mellifera honey from Kenya. Int. J. Food Sci.

Technol. 2020, 55(3), 1246-1254. https://doi.org/10.1111/ijfs.14403.

6.

Rios, F.; Lobo, M.; Samman, N. Acceptability of

beehive products as ingredients in quinoa bars. J. Sci. Food Agric. 2018, 98, 174-182.

https://doi.org/10.1002/jsfa.8452.

7.

Cosme-Alonso, V.; Martínez-Lifshitz, M.E.;

Mani-López, E. Yogurt supplemented with bee pollen: Physicochemical and sensory

properties, and in vitro pollen digestibility. J. Agric. Food Sci. Biotechnol.

2023, 1(3), 224-231. https://doi.org/10.58985/jafsb.2023.v01i03.27.

8.

Mutlu, C.; Tontul, S.A.; Erbaş, M. Production of a

minimally processed jelly candy for children using honey instead of sugar. LWT, 2028, 93, 499-505.

https://doi.org/10.1016/j.lwt.2018.03.064

9.

Schrieber R.; Gareis H. Gelatine handbook:

theory and industrial practice. John Wiley & Sons, Weinheim, Germany, 2007

10.

Zepon, K.M.; Martins, M.M.; Marques, M.S.;

Heckler, J.M.; Morisso, F.D.P.; Moreira, M.; Ziulkoski, A.L.; Kanis, L.A. Smart

wound dressing based on κ–carrageenan/locust bean gum/cranberry extract for

monitoring bacterial infections. Carbohyd.

Polym. 2019, 206, 362-370. https://doi.org/10.1016/j.carbpol.2018.11.014,

11.

He, H.; Ye J.; Zhang, X.; Huang, Y.; Li X.;

Xiao, M. κ-Carrageenan/locust bean gum as hard capsule gelling agents. Carbohyd. Polym. 2017, 175, 417-424.

https://doi:10.1016/j.carbpol.2017.07.049,

12.

Tan, H.L.; Tan, T.C.; Easa, A.M. The use of selected

polysaccharide to enhance cooking quality and hardness of zero‐salt noodles. Int. J. Food Sci.

Technol. 2018, 53, 1603-1610.

https://doi.org/10.1111/ijfs.13742.

13.

Phillips, G.O.; Williams, P.A. Handbook of polysaccharide,

4th edn, Cambridge, UK, 2009.

14.

Pinheiro, A.C.; Bourbon, A.I.; Rocha, C.;

Ribeiro, C.; Maia, J.M.; Gonçalves, M.P.; Texeira, A.A.; Vicente, A.A.

Rheological characterization of κ-carrageenan/galactomannan and

xanthan/galactomannan gels: Comparison of galactomannans from non-traditional

sources with conventional galactomannans. Carbohyd. Polym. 2011, 83(2), 392-399.

https://doi.org/10.1016/j.carbpol.2010.07.058.

15.

Nguyen, H.T.L.; Katopo, L.; Pang, E.;

Mantri, N.; Kasapis, S. Structural variation in gelatin networks from low to

high-solid systems effected by honey addition. Food Res. Int. 2019, 121,

319-325. https://doi:

10.1016/j.foodres.2019.03.048.

16.

Nishinari. K.; Fang. Y. Perception and

measurement of food texture: Solid foods. J. Texture Stud. 2018, 49, 160-201. https://doi.org/10.1111/jtxs.12327.

17.

Codex Alimentarius Commission. Recommended

methods of analysis and sampling. 2021 Available on: https://www.fao.org/fao-who-codexalimentarius/codex-texts/list-standards/es/

(accessed on 10th January, 2024).

18.

GMIA Standard methods

for the testing of edible gelatine. Official Procedure of the Gelatin

Manufacturers Institute of America, 2023, 7-11.

19.

Association of Official Analytical Chemists. Official

Methods of Analysis, 22nd Edn, Washington, D.C., 2023.

20.

Ares, G.; Dauber, C.; Fernández, E.;

Giménez, A.; Varela, P. Penalty analysis based on CATA questions to identify

drivers of liking and directions for product reformulation. Food Qual Prefer.

2024, 32, 65-76. https://doi.org/10.1016/j.foodqual.2013.05.014.

21.

Ares, G.; Jaeger, S.R. Check-all-that-apply

questions: Influence of attribute order on sensory product characterization. Food Qual. Prefer. 2013, 28, 141-153.

https://doi.org/10.1016/j.foodqual.2012.08.016.

22.

Evageliou, V.; Richardson, R.K.; Morris, E.R. Effect of

pH, sugar type and thermal annealing on

high-methoxy pectin gels. Carbohyd Polym. 2000, 42, 245-259.

https://doi.org/10.1016/S0144-8617(99)00191-5.

23.

Norziah, M.H.; Foo, S.L.; Karim, A.A. Rheological studies on

mixtures of agar (Gracilariachangii) and kappa-carrageenan. Food Hydrocoll.

2006, 20, 204-217. https://doi.org/10.1016/j.foodhyd.2005.03.020.

24.

Damodaran, S.; Parkin, K.L. Química

de alimentos de Fennema, 5th

edn, CRC Press, 2017.

25.

Ismaiel, S.; Al Kahtani, S.; Adgaba,

N.; Al-Ghamdi, A.A.; Zulail, A. Factors that affect consumption patterns

and market demands for honey in the Kingdom of Saudi Arabia. Nutr. Food Sci.

2014, 5, 1725-1737. https://doi.org/10.4236/fns.2014.517186.

26.

Cosmina, M.; Gallenti, G.; Marangon,

F.; Troiano, S. Reprint of “Attitudes towards honey among Italian consumers:

A choice experiment approach”.

Appetite. 2016, 106, 110-116.

https://doi.org/10.1016/j.appet.2016.08.005.

27. Castiglioni, S.; Stefano, M.; Pisani, M.; Carloni, P. Geographical characterisation of multifloral honeys from the Marche region (Italy) according to their antioxidant activity and colour using a chemometric approach. Int. J. Food Sci. Technol. 2018, 53(3), 571-581. https://doi.org/10.1111/ijfs.13630.

This work is licensed under the

Creative Commons Attribution

4.0

License (CC BY-NC 4.0).

Abstract

The work aimed to develop a gelled

product based on honey and a polysaccharide system. Polysaccharides used as gelling and

texturizing agents were ĸ-carrageenan (Car) and locust bean gum (LBG). The gel

with honey was developed using a rotational central composite design (RCCD) with

three variables (concentration of polysaccharides, Car percentage in polysaccharides, and honey content) and Bloom Strength (BS)

was used as a response variable. The BS of the gelled

system increased linearly with the content in Car and LBG used as gelling and

texturizing agents. The Car-LBG system showed maximum values at 64.85% of Car

and 35.15 % of LBG. Honey concentration in the Car-LBG system increased BS to a

maximum value of 14.47g/100g. The rheological profile (Gꞌ, Gꞌꞌ, tan δ) of

the obtained product showed the typical behavior of polysaccharide gels. The

gelation (Tg = 44.5±0.4 °C) and melting (Tm = 66.1±0.2

°C) temperatures were determined. The attributes that could increase the gelled

product's acceptance were identified: aroma and taste of honey. The product had

significant amounts of honey (sweetener) and adequate sensory properties that

make it attractive for the formulation of commercial gels using

polysaccharides. This novel product has the potential to expand the use

of honey and polysaccharides in the food industry.

Abstract Keywords

Gels,

honey, carrageenan, locust bean gum, bloom strength, acceptability.

This work is licensed under the

Creative Commons Attribution

4.0

License (CC BY-NC 4.0).

This work is licensed under the

Creative Commons Attribution 4.0

License.(CC BY-NC 4.0).